Due to ever increasing complexities of long term customers ‘requirements for the solutions to their material handling needs, we have to have readily available original designs of entire projects. Astos Machinery in close collaboration with its sister company Machinery Design conducts continuously R&D resulting in many highly specialized technical designs and solutions for varied technological requirements.

Presentation of successful projects

Stamping facility of Toyota Motor Company - Saint Petersburg, Russia

Astos Machinery has been the overall winner of the European selection procedure for the supply of the scrap metal conveyor system for the progressive stamping press. We turned into an exclusive supplier of the system for the new Toyota stamping plant thanks to great deal of experience.

To be linked with Toyota as its exclusive supplier of the system for the new stamping plant we had to proof to be a worthy partner by providing affirmation of our long term experience and references of excellence by our previous customers.

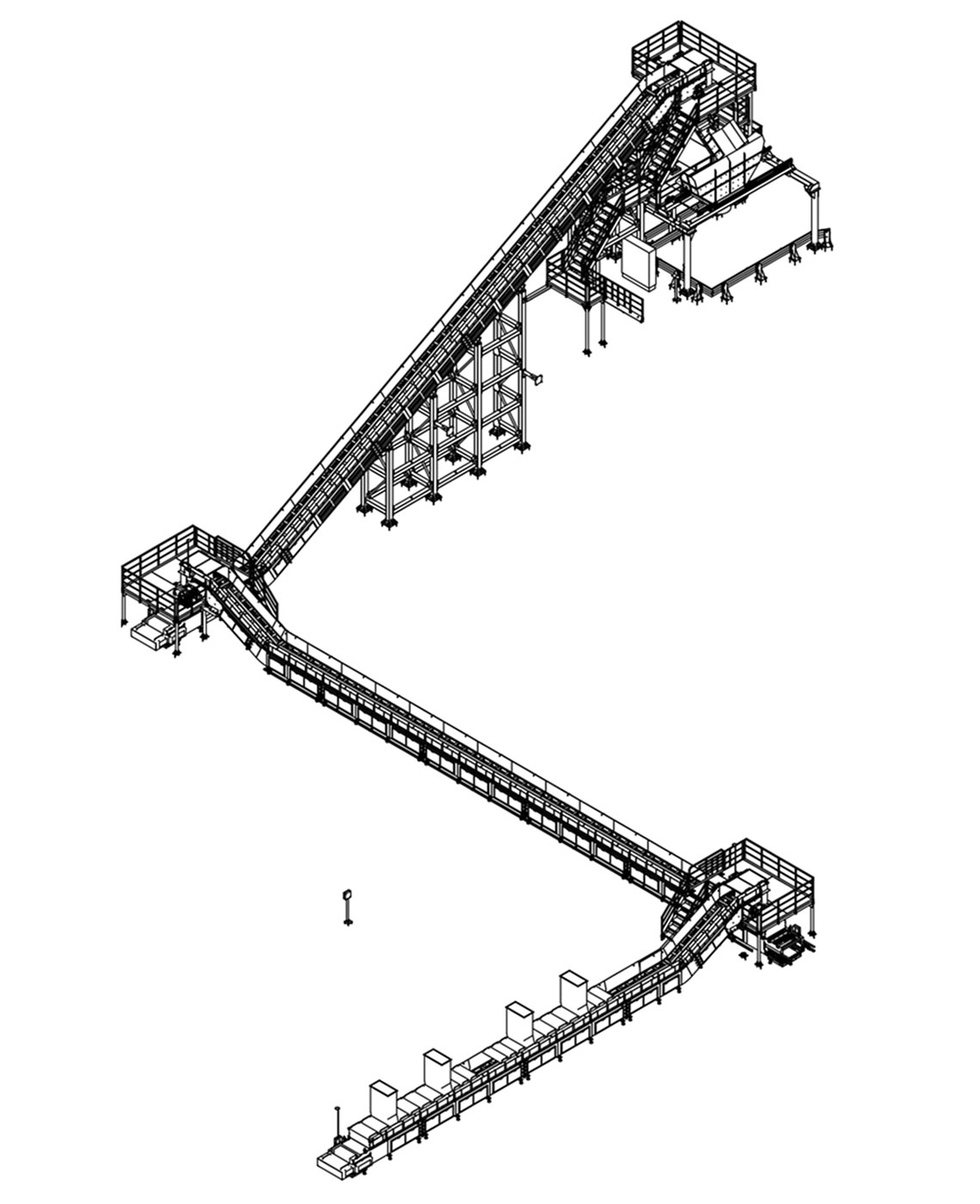

The conveyor system consists of 3 specifically designed conveyors, number of service platforms with staircases and a tip over hopper. The staircase at the discharge conveyor reaches the height of 12 meters. The system is fully automated, fitted with integrated control technology which is directly communicating with the press. The load capacity of the conveyor system is 6 tons of scrap metal from several stamping presses. Overall the system’s capacity is up to 110 tons! These amounts put pressure on the logistic side of things too. The space needed for goods waiting to be despatched would take up a good sized football pitch.

The acceptance testing has been attended by 12 experts from Toyota Tsusho Europe and Toyota Motor Corporation, where the system has been test run and the logic controller system has been set.

The conveyor’s length is 26 m in total and this has been assembled together with one of the service platforms on the factories floor. The advanced and well thought through details are what makes this project unique. Our technical solutions to problems which might occur in such a demanding environment are what set us apart from a competition. The bottom of the conveyor is with a slight incline to ease the outflow of coolant into the central receptacle. In order to allow the best access possible for the servicing and maintenance staff, the bearings have a special placement at the inside of the conveyor. The tightening of the belt, the inspection openings in the side of the conveyor’s body were just few improvements which make the conveyor virtually maintenance free and they increase the overall longevity of the conveyor system. The abrasion resistant steel with a guaranteed minimum surface hardness Hardox 400 has been used to reinforce the chain guide tracks and floor plate of the conveyors.