Belt drum filtration

Drum belt filter is a device designed for filtration of many kinds of liquids contaminated by mechanical particles, such as abrasion from grinding, chips from machining, dross from alloy manufacture, sludge from washing and hardening processes and many other procedures. DBF filtration operates by collecting impurities on the surface of the filter cloth through which the contaminated liquid flows. The filter cloth is unwound from a supply reel and deposited on a driving mesh belt. The filter cloth is pressed against the belt by a pair of squeeze rollers, which at the same time prevent leakage of liquid outside the filter. Liquid impurities settle on the filter cloth and form a sludge layer called filter cake (FC). Advantages of DBF:

Advantages of DBF:

- Gradual saturation of the pores of the filter cloth and thickening of the impurities also trap particles of a smaller size than the pores of the filter cloth.

- When the FC is so saturated that liquid is no longer able to flow through, the level in the vessel increases. This increases the hydrostatic pressure and causes additional liquid to pass through the filter cloth. As soon as FC becomes completely impermeable, the liquid level increases to the extent that it switches the level switch, which triggers the movement of the mesh belt and this automatically feeds the required amount of clean filter cloth. This restores the flow of liquid and creates a new FC. The contaminated cloth with FC is ejected from the DBF and falls into the waste container.

- The cloth supply reel is scanned by the reel sensor.

- The device can be equipped with a wiper blade to clean the filter cloth of coarse dirt.

Technical description

We produce a complete range of drum belt filters for contaminated liquid discharge from 100 l/min to 2,200 l/min.

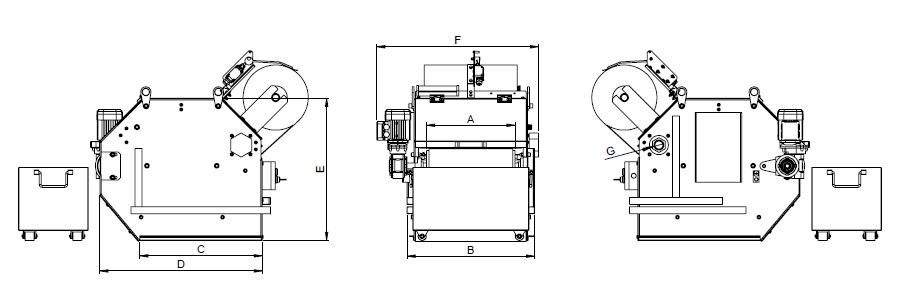

| TYP | Flow rate VG5* | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|---|

| [l/min] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [coul] | |

| PFB100.04 | 100 | 400 | 568 | 522 | 698 | 611 | 860 | 1 1/2" |

| PFB150.06 | 150 | 600 | 768 | 522 | 698 | 611 | 1060 | 1 1/2" |

| PFB250.06 | 250 | 600 | 768 | 762 | 998 | 901 | 1060 | 1 1/2" |

| PFB450.10 | 450 | 1000 | 1168 | 762 | 998 | 901 | 1460 | 1 1/2" |

| PFB700.08 | 700 | 800 | 968 | 1165 | 1470 | 1320 | 1260 | 3" |

| PFB1000.10 | 1000 | 1000 | 1168 | 1165 | 1470 | 1320 | 1460 | 3" |

| PFB1600.15 | 1600 | 1500 | 1668 | 1165 | 1470 | 1320 | 1820 | 3" |

| PFB2200.20 | 2200 | 2000 | 2168 | 1165 | 1470 | 1320 | 2460 | 3" |

*Filtration fabric 70g/qm, Filter fineness 35 µm

- The basic parameters for determining the type of filter and filter belt are: filtered medium, input concentration, size and shape of filtered impurities, filter belt permeability and filter fineness.

- The nominal flow rate in the table is the mean value calculated for water-based liquids.

- We will prepare the optimum solution based on the given parameters or samples of sludge and liquids for filtration analysis in our testing laboratory.

If you need further assistance or have any special requirements related to Band drum filtration, please do not hesitate to contact our team of experts. Contact information.