Drum filtration station and a central filtration station

This circuit filtration equipment is designed for filtration of different types of liquid contaminated by mechanical particles, e.g. ground-off material from grinding, chips from machining, iron scales from alloy formation, sludge from washing and hardening processes, etc. When the liquid passes through the DFS and CFS equipment, it is decontaminated and may be used in the technological process again.

Both equipment types are custom-manufactured based on individual parameters and requirements, e.g. flow rate, medium to be filtered, viscosity, requested filtration depth,

input concentration, size and shape of filtered particles.

The definite parameter setting and configuration are prepared based on your parameters or sludge and liquid samples determined for a filtration that are subsequently analysed in our laboratory. The equipment is designed with optimal built-in dimensions and necessary components and blocks.

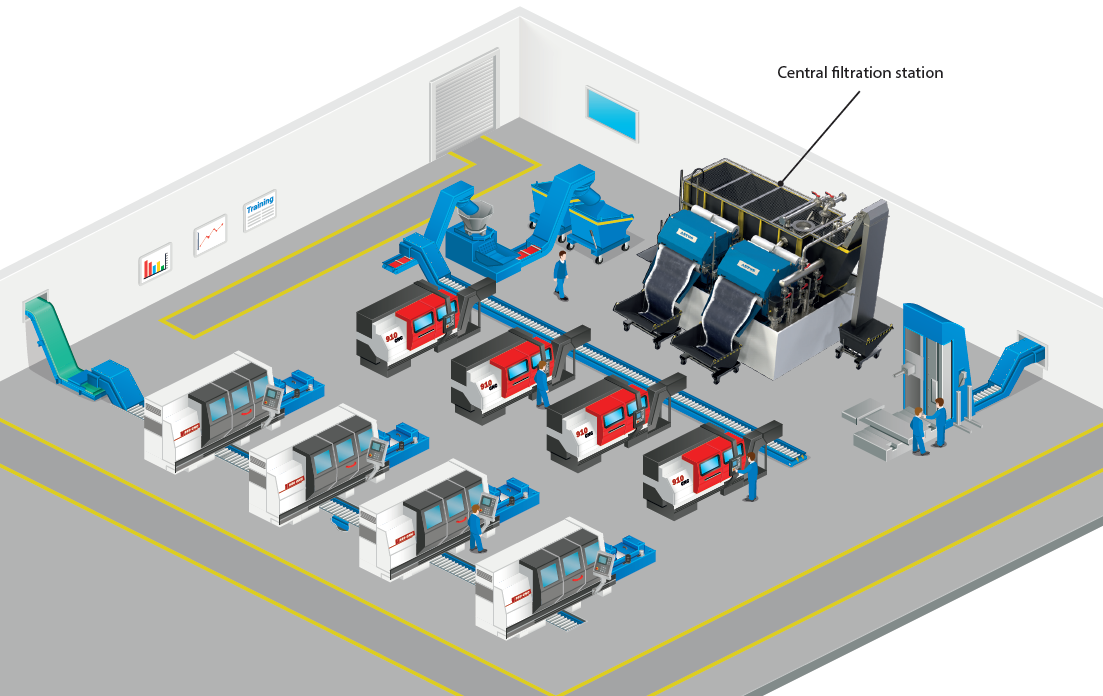

Example of production floor