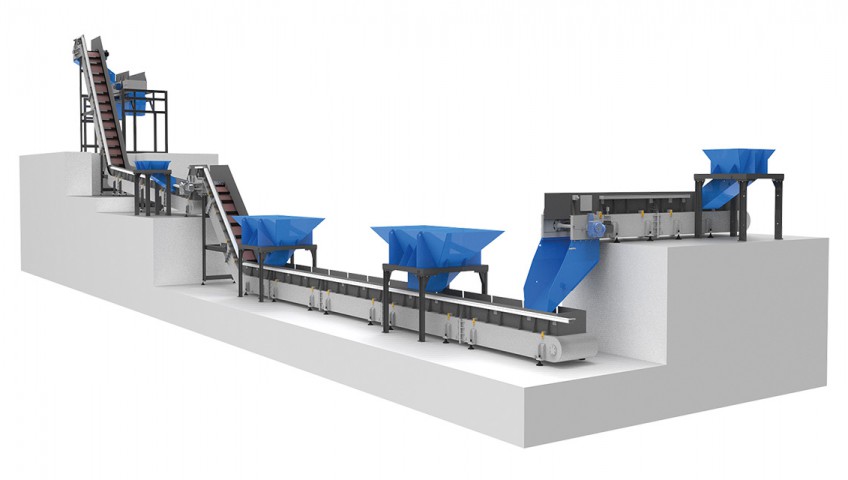

SPD – Special solution

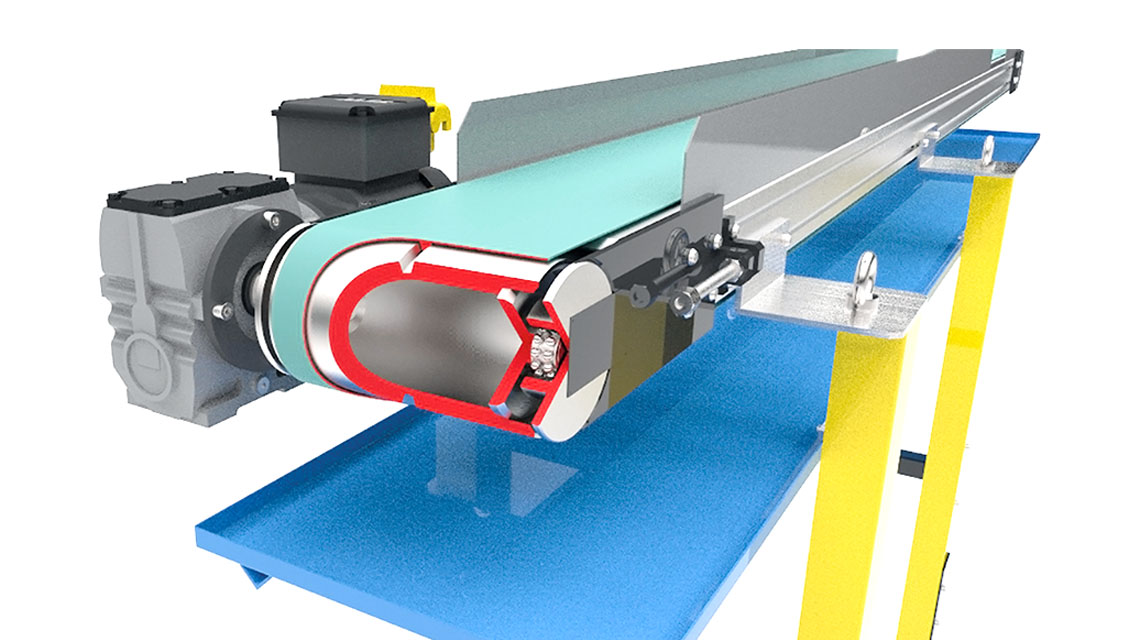

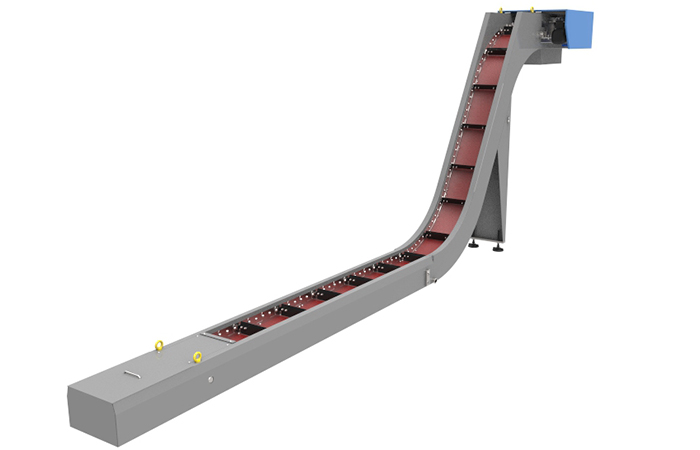

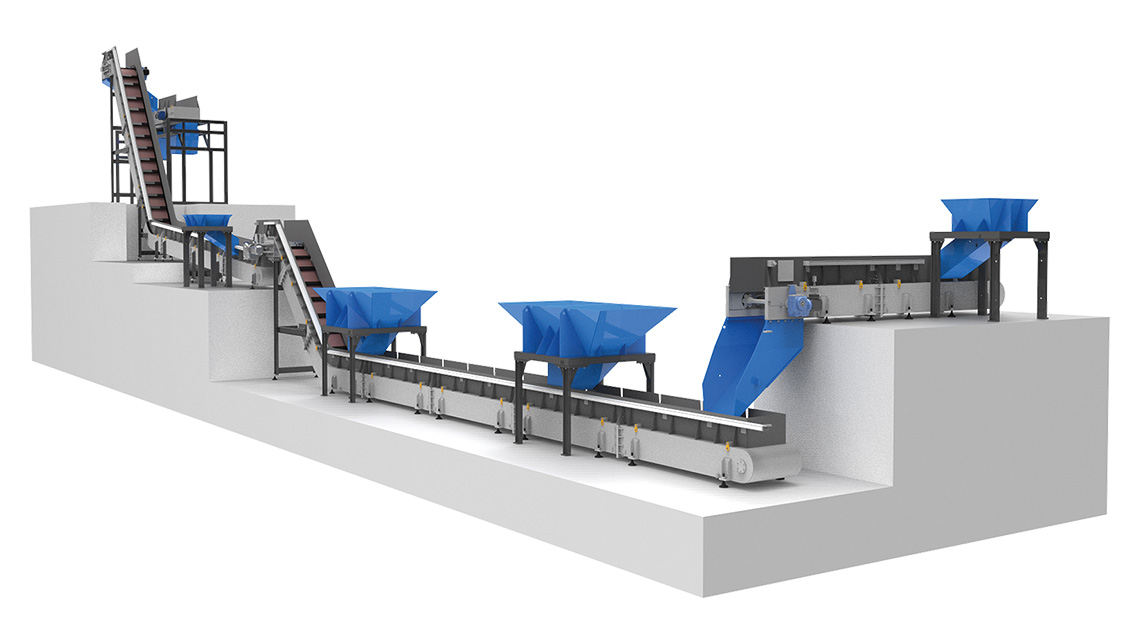

Belt conveyor

Belt conveyors are durable and versatile. Used for transporting of small, irregular shaped objects, small parts, loose material etc. The belts are of premium quality with reduced stretch and high puncture resistance.

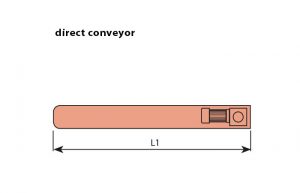

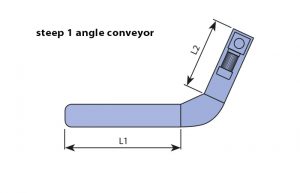

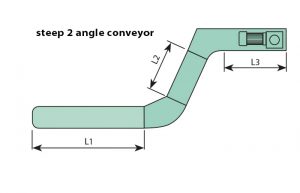

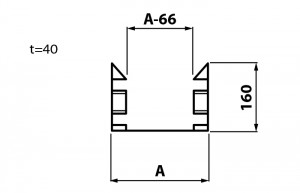

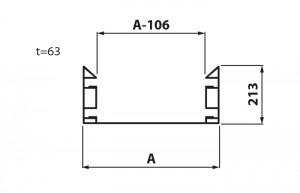

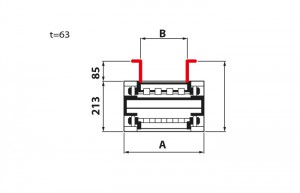

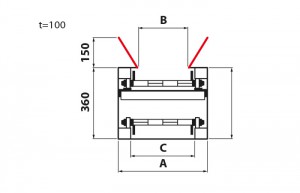

Classification as per shape

The drive of the conveyor can be mounted either on left or right hand side.

Advantages of the belt conveyor

- versatility and variability

- diversity in the use

- can be used in automated distribution, in warehousing and on manufacturing assembly lines as well as in service sector (banks, post services, shops etc.) and secondary industries (textile, paper, glass - industry)

If you need further assistance or have any special requirements related to our belt conveyors, please do not hesitate to contact our team of experts. Contact information.