Conveyor line for transport of punching waste out of an automatic stamping facility

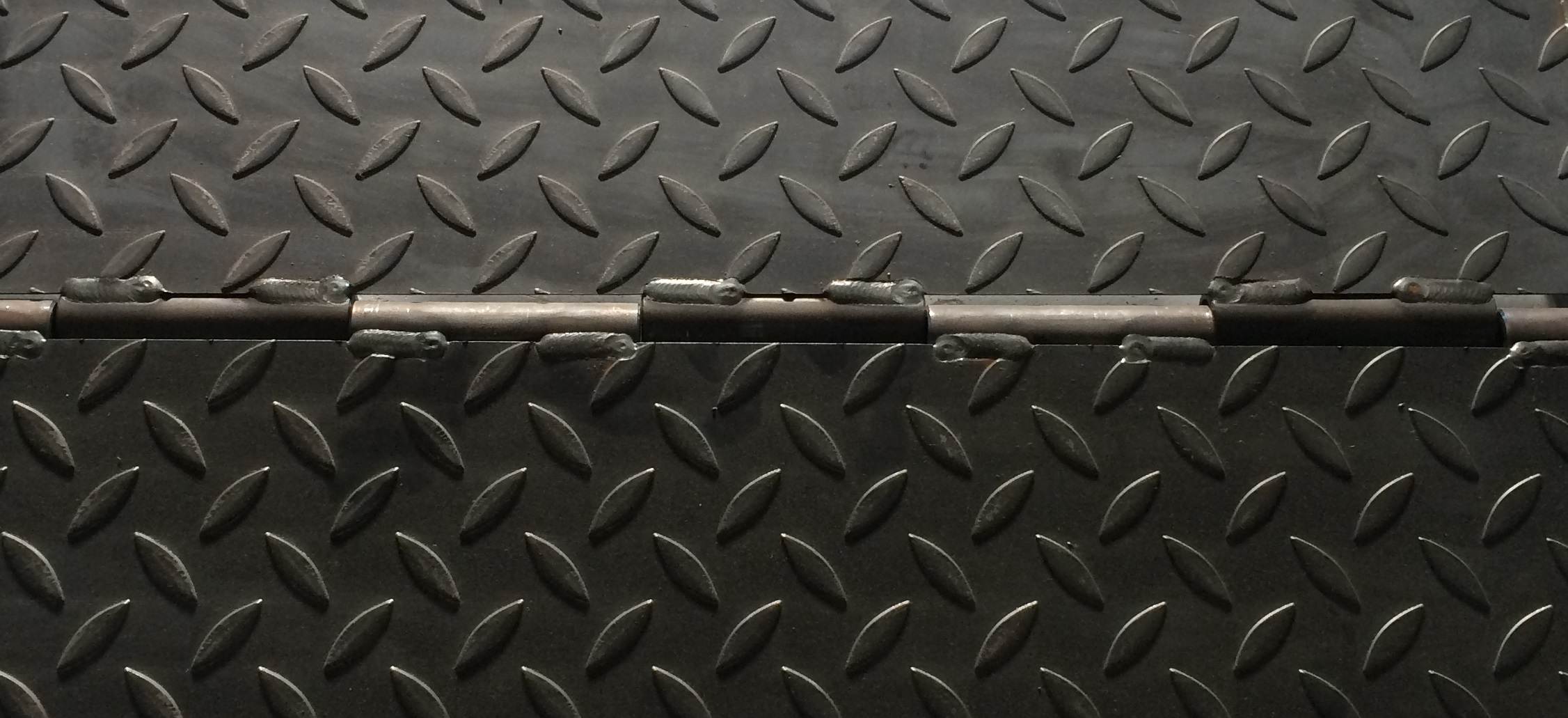

The setup of two hinged steel belt conveyors T160 with reinforced welded construction for a stamping facility consisting of several presses from 250-500 tonnes. For accuracy the belt’s links are robotic welded. (see picture)

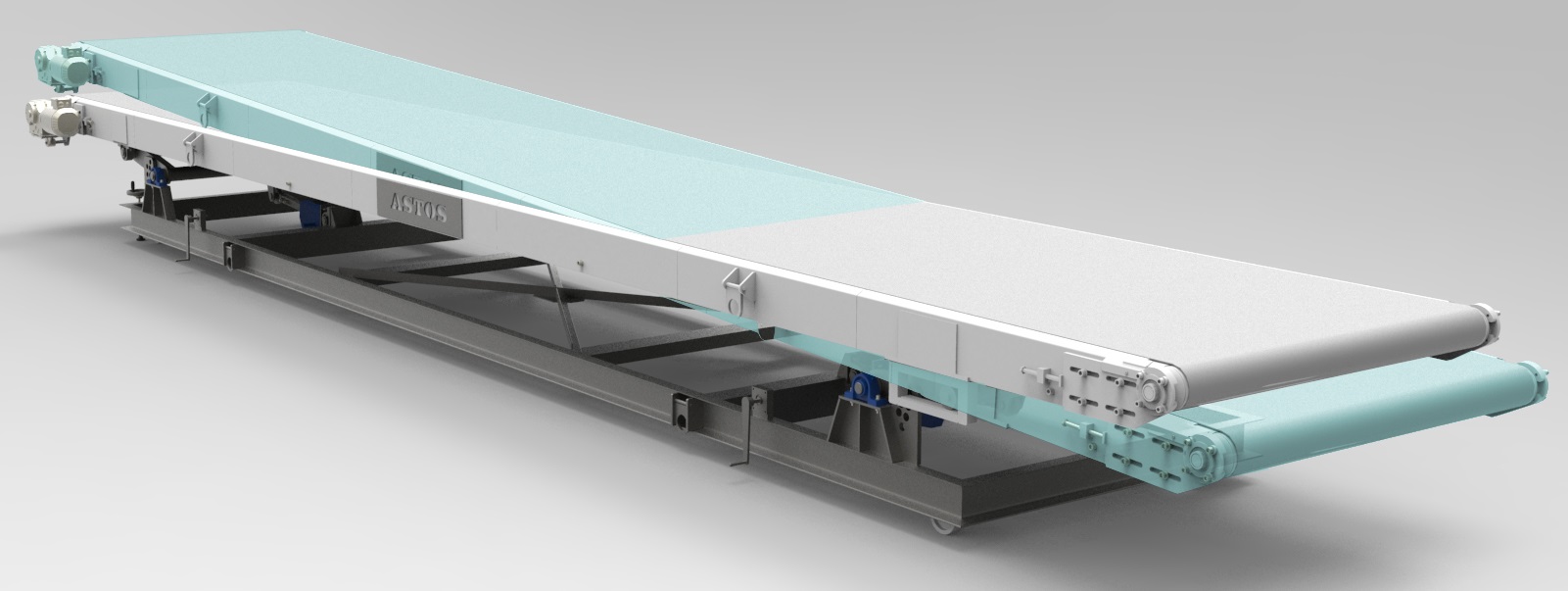

The collecting conveyor is over 60 m long and the second conveyor- the discharge conveyor- runs over the span of 24 m with 7 meters of superelevation.

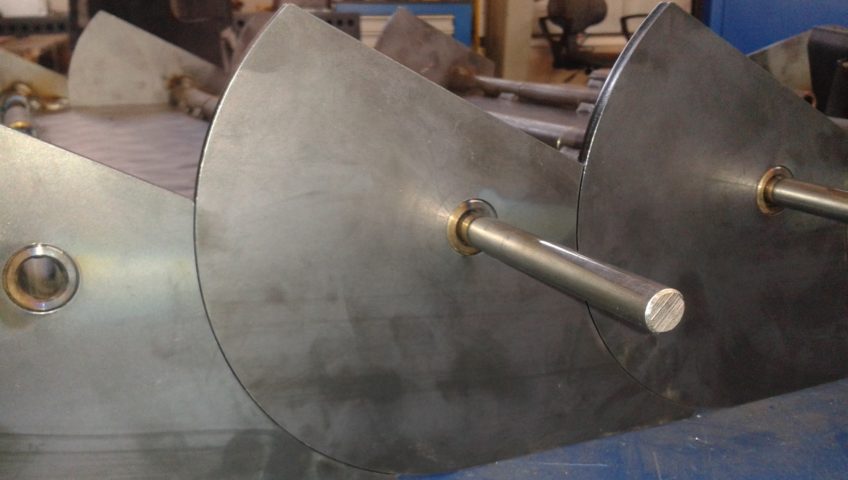

The discharge conveyor transports the metal scrap into a rotary discharge chute. This in turn is regulated with the Siemens control system.

Both conveyors are fitted with safety switches and automatic lubrication systems. In order to efficiently monitor and control the optimal level of scrap in the containers, the discharge chute is equipped with sensors. These activate the change of the position of the chute, after the containers are filled.

Automatic line will be assembled during the month of October in subsidiary of a significant German supplier for automotive industry.

Currently it is the first stage of the conveyor line. The second stage is planned for the year 2017

Picture: Hinged steel belt links –robotic welded